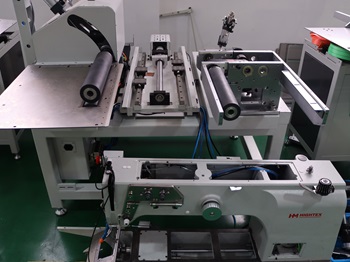

Programmable sewing machine

WEB911-7X Revolutionary new automated sewing machine for webbing slings -- the fully automatic webbing lifting slings sewing machine

The major advantages:

1. WEB911 is a revolutionary new automated sewing machine for saving labor cost and increasing productivity, in the production of webbing lifting slings. It can automatically finished all sewing tasks in one process, included (1) Assembly seams for joining layers of flat webbing together; (2) Reinforcement stitch (zig-zag pattern stitching ) for reinforced eyes (loops); (3) Straight stitches across the webbing;

2. This textile slings sewing automation equipped with largest rotary hook in today market, that allows you to use extra thick thread up to metric size #4,V693, T-700, 2000d X3;

3. The 7 times larger bobbin capacity could significantly enhance sewing capacity. This improvement would not only reduce downtime but also decrease the frequency of resultant issues, streamlining the overall sewing process for an advanced CNC sewing machine;

4. The bobbin thread detector will automatically stop machine when bobbin thread runs out, as a result, sewing operators can concentrate on their work without worrying about the bobbin thread, increasing the productivity, and it is possible to run 2 or 3 machines with only one person, great for saving labor cost;

5. The thread trimmer offers outstanding reliability and durability. The ideal application for the device is the sewing of webbing lifting strap with thick synthetic threads;

6. The machine also has a built-in lubrication system that ensures smooth and consistent sewing, reducing the need for frequent oiling and maintenance;

7. Sewing automation improves productivity as well as the quality of seams by minimizing human intervention and preventing manufacturing mistakes, the price of fully automated sewing machine can be recovered within 2-3 years by reducing labor costs;

8. For such industrial automation system, quality, reliability and durability is the critical success factors. HighTex was founded as a company that places quality over quantity. We then test sew the machine over and over again to insure the machine will work flawlessly in production situations. The product reliability testing phase is expected to last approximately 2 months, so we recommend ordering 2-3 months prior to put into use;

9. Machine’s value isn’t just determined by its purchase price but also by the quality of after-sales support. We also offer comprehensive training ensures that customers can fully utilize the product’s capabilities, ultimately benefiting both parties;

10. Additionally, we have 20 years of experience providing turn-key programmable sewing machine systems to a global market. Vast experience in serving customers from the productions of cargo lashing straps, safety harnesses and lifting slings. HighTex has machines for various applications, which through the vast experience of the HighTex Technical Service can be incorporated into production lines of multiple textile slings industries, in order to reduce the labor required for sewing processes.

Applications:

(1) Assembly seams for joining layers of flat webbing together;

(2) Reinforcement stitch (zig-zag pattern stitching ) for reinforced eyes (loops);

(3) Straight stitches across the webbing.