Servo motor

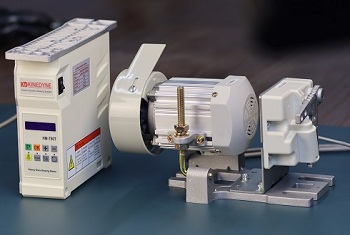

Kinedyne HM-750T is a powerful, quiet and reliable energy saving servo motor perfect for all types of heavy-duty industrial sewing machines. The HM-750T is specifically designed for large barrel shuttle hook type extra heavy-duty sewing machines, and is the first motor made specifically for these types of machines.

The major advantages:

1. Extra powerful servo motor for heavy duty industrial sewing machine

This premium quality energy saving servo motor offers an awesome 750 Watts output power. That is approximately 1 horsepower (HP) of performance and power! It can drive any extra heavy duty industrial sewing machine without any difficulty.

2. High torque clutchless electronic AC servo motor

The HM-750T electronic servo motor produces an awesome 7.9 Nm of torque which means extremely strong needle penetration force and better performance in super hard leather and technical textiles.

3. Super quiet energy saving brushless servo motor

Absolutely silent with no vibration noise or buzzing like other models on the market. The constant noise that is normally associated with sewing motors (clutch motors) is almost entirely eliminated, creating a more pleasant work environment.

4. Speed adjustable sewing machine motor

Speed is adjustable by a simple setting (from 300RPM to 3000RPM) that allowing you to slow down your machine and sew stitch by stitch. This makes sewing detailed work much easier. Also ideal for beginners.

5. Energy saving servo motor

What sets the Kinedyne HM-750T apart from other motors is a completely redesigned PC board which allows for true low current start up. There are two advantages to this. First, it allows for a more stable amperage draw, and reduces the energy consumption by an astonishing 60%-80%.

6. High efficiency sewing machine servo motor with best price

It is a high efficiency sewing machine servo motor that supports electric over pneumatic air system for automatic functions such as pneumatic presser foot lift, pneumatic reverse stitch, automatic thread trimmer, needle cooler and puller lift, your productivity may increase substantially (20-40%).

7. Stable & Accurate Speed Control

The heavy-duty industrial sewing machine servo motor adopts a sinusoidal wave current drive. The sinusoidal wave current drive method provides unparalleled power and torque, thus the motor runs gently and smoothly when motor shifts between low, middle and high speed. This provides very accurate speed control!

8. Kinetic dynamic sewing system

Different machines and / or materials require different torque, power and speed. It is similar to gears for a car. The sewing motor can be adapted for slow powerful use that requires a lot of torque and horsepower, or used in faster sewing situations that require less torque and more speed.

9. Compact and easy to install servo sewing machine motor

The mounting system is the common universal 3-hole design used in all clutch and servo motors. Installation is easy and hassle free, with no need for a technician or electrician.

10. Needle positioning servo motor great for time-saving

Kinedyne needle positioner synchronizer allow you to stop needle in the down AND up position. When you want to pivot the work to change sewing direction, the needle stops in down position for handy fabric movement (will not lose the stitch), sew corners or pivot with ease. At end of sewing, stops needle in up position so that the work can be removed, and thread snipped.

Applications:

This durable, robust and extra strong energy saving servo motor perfect for all types of heavy duty long arm and extra heavy duty industrial sewing machines, such as Seiko SLH-2B, Juki TSC-441, Juki TNU-243, Durkopp Adler 204-370, Durkopp Adler 205-370, Seiko CH-2B, CH-6B,CH -7B,CH -8B,TH-6B, -TH8B, Durkopp Adler 969, Durkopp Adler 967,Juki LG-158,Seiko JW-28BL-30, Durkopp Adler 221

How to save money on your electric bill?

Energy saving servo motor for industrial sewing machines is the key!

Kinedyne HM-750T is the best quality and best price AC servo motor for all heavy duty industrial sewing machines in today market!!

The HM-750T motor is built to last. It made to the highest quality and exacting standards and materials available. Each electronic board and controller are made of the best quality electronic components, assuring you many years of trouble-free performance.

The Kinedyne HM-750T servo motor is great for advanced heavy duty industrial sewing machines that equipped with automatic functions such as pneumatic presser foot lift, pneumatic reverse, automatic thread trimmer, needle cooler and puller lift etc.

The advanced robust accurate speed control device can stop the sewing machine almost immediately at any sewing speed, and accelerate within 0.3 second, ideal for the sewing production that require very often intermittent stop for handling material, such as Big Bags / FIBCs / Bulk Bags.

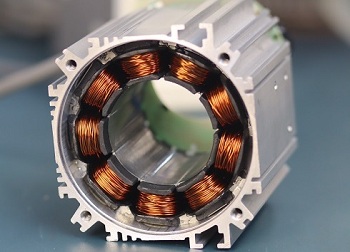

The Kinedyne HM-750T features pure copper coils in the motor winding for better current flow and high-temperature resistance. This also allows the motor to be highly energy efficient -- saving 60-80 percent electricity. Usually the cost of servo motor can be recovered within 2-3 years by saving money on electricity. However the advantage of time savings and labor cost saving will make the actual return on investment faster.

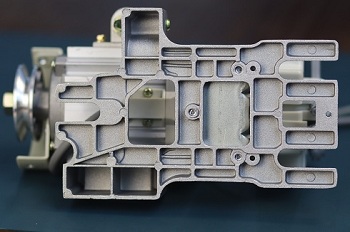

The Kinedyne HM-750T has one of the most advanced cooling systems in the sewing machine motor industry. The cooling surface is much larger and more effective than other motors of the same class. This allows the motor to run with little temperature increase and also prolongs the life of sensitive electronic components. The net result is a much longer lasting, more reliable motor.

The mounting base of the Kinedyne HM-750T servo motor is made of a very thick and strong metal alloy. This base is more than able to withstand the high torque and horsepower which the motor generates. It provides a stable and secure mount for the motor.

The synchronizer of Kinedyne needle position servo motor allows you to stop the needle in up AND (not OR) down positions which is not found on competitors' servo motors. This needle position synchronizer is ideal for turning corner stitching or any other applications that require UP and DOWN needle positioning. "How many times a day do you have to remove your hand from your work, move the hand wheel to lift needle, then remove the material?” Kinedyne HM-750T is great for time-saving!

The belt guard provides full and complete protection of the motor pulley and belt. This will greatly reduce any chance of operator injury.

If you have any questions or concerns, please feel free to contact us at info@automatic-sewing.com, thank you!