Technology

Want to start your own manufacturing business of synthetic slings?

Need to expand your production capacity and improve seam quality?

What heavy duty industrial sewing machine would best meet your needs?

It is very important to choose right industrial sewing equipment suitable for your production. Please let your technicians or engineers read this guide carefully before ordering machine.

Many end users interchange nylon and polyester, there are differences in performance, stretching, etc. but sewing polyester web slings is similar to nylon web slings. Generally there are 2 types industrial sewing machines used in manufacture of synthetic slings & straps made of Nylon, Polyester and Polypropylene:

1. Plain industrial straight stitch sewing machine to assemble flat webbing straps & slings

Click here for DEMO video

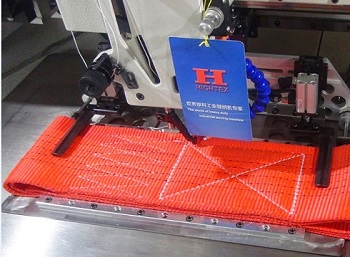

2. Heavy duty programmable pattern sewing machine for reinforced stitching slings and harness

Click here for DEMO video

In Part (I), we will guide you to select heavy duty plain sewing machine for assembling synthetic lifting slings & cargo lashing straps (Ratchet Tie Down).

(1) Thickness of slings and straps

Nylon and Polyester synthetic slings or straps can vary in thickness for different applications. Here list the popular webbing slings sewing machines for different thickness.

HIGHTEX # 7367: 2-7 mm thickness

HIGHTEX # 7373ECO: 4-14 mm thickness

HIGHTEX #7243: 4-14 mm thickness

HIGHTEX #7204: 4-18 mm thickness

HIGHTEX #7373BV: 8-20 mm thickness

HIGHTEX #733CS: 8-25 mm thickness

(Note: above recommendation base on optimal stitch formation.)

(2) Width of slings and straps

Nylon and Polyester synthetic slings or straps can vary in width. So you need to consider under arm clearance (to the right of the needle)

HIGHTEX # 7367-------------------400 mm

HIGHTEX # 7373ECO---------------420 mm

HIGHTEX #7243-------------------- 420 mm

HIGHTEX #7204--------------------320 mm

HIGHTEX #7373BV-----------------420 mm

HIGHTEX #733CS-------------------420 mm

(3) Thread size

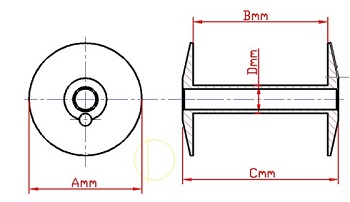

Synthetic web slings must be complied strictly with safety requirements. The quality and size of sewing threads also determine safety and durability of the sewn seams. Thus extremely thick thread always used in the production of synthetic lifting slings and cargo lashing straps (Ratchet Tie Down). You should consider both bobbin capacity (bigger bobbin reduce time of changing bottom thread) and the max. sewing thread that machine can process:

#7367 bobbin size: A=34.5/ B=12.3/C=15.1/D=9.5 Max. thread size 10: V277, T-270, 840dx3

#7373ECO bobbin size: A=23.0/ B=26.5/ C=30.0/ D=9.0 Max. thread size 8: V346, T-350, 1100dx3

#7243 bobbin size(mm): A=24.0/ B=25.5/ C=30.0/ D=7.5 Max. thread size 7: V415, T-400, 1300dx3

#7204 bobbin size(mm): A=24.0/B=25.0/ C=30.5/ D=7.5 Max. thread size 7: V415, T-400, 1300dx3

#7373BV bobbin size: A=23.0/ B=26.5/ C=30.0/ D=9.0 Max. thread size 8: V346, T-350, 1100dx3

#733 bobbin size (mm): A=32.0/ B=38.0/ C=44.1/ D=7.7 Max. thread size 4: V693, T-700, 2000dx3

The thread size must match up needle size. If you are to sew webbing slings and straps with different size of thread, it is better purchase different size of needles, together with machines.

(4) Feeding system of machine

Synthetic web slings are difficult to sew, especially when stitch multiple layers of webbing together, because they are tough, slipped, heavy, awkward and stiff. Walking foot industrial sewing machine with reverse is almost necessary, the drop feed (feed dog) and alternating (walking) presser foot feed synchronously, keeping all layers of webbing even and smooth while sewing them together.

Triple-feed is the most expensive sewing technology, most large slings and straps manufacturers for serving high-end industrial markets are using triple feed industrial sewing machines. Triple feed sewing machines have two alternating presser feet which move the material by synchronizing the motion of the needle bar, the inside presser foot and the bottom feed dog. While the material is being moved (forward or reverse), the outside foot is lifted off the top of the work. This allows the needle, inner foot and feed dog to easily transport all of the layers together, until the preset stitch length is reached.

Triple feed is not vital but it really helps when stitch multiple layers of synthetic web slings together. It saves time and save spare piece. If budget allows, your order should include at least one triple feed sewing machine.

HIGHTEX #7367: walking foot machine

HIGHTEX #7373ECO: walking foot machine

HIGHTEX #7243: triple feed machine

HIGHTEX #7204: triple feed machine

HIGHTEX #7373BV: walking foot machine

HIGHTEX #733CS: walking foot machine

(5) Number of needle

In the production of lifting slings & cargo lashing straps (Ratchet Tie Down), single needle straight stitch sewing machine is the necessity. In order to improve efficiency and obtain uniform stitch, some textile slings manufacturers are using 728 class extra heavy duty double needle compound feed and walking foot sewing machine to stitch both edges of sling & straps at same time. With this machine, can operator can save 1/2 time, but please note this machine can sew with max. 346 thread (1100d×3 or Tex size T-350), and the max. needle gauge set (the distance between two needle) is 2 1/2" (63.5mm).

(6) Your sewing experience

HIGHTEX series heavy duty industrial sewing machines are interchangeable with some popular sewing equipment in this field, such as Durkopp Adler 204-370 and Juki TNU-243. If you already worked with these slings sewing machines, you can get the same equipment and spare parts from us. If you are a beginner, you should take your skill level and max budget into consideration when you plan to start your own production of synthetic lifting slings & cargo lashing straps(Ratchet Tie Down).

(7) Optional sewing devices

Below devices will help you achieve maximum productivity and optimum seam quality, you can consider when purchasing sewing machine.

1. Automatic presser foot lift: presser foot lift by the switch on machine, time-saving and labour-saving.

2. Automatic reverse stitch (back tacking): reverse feed controlled by the switch on machine, save operator time and labour. Also great for reverse stitch entirely slings and straps.

3. Needle cooler: when sewing thick synthetic web slings, the needle may become hot and cause needle breakage & thread burn through, if you sew fast. The needle cooling system can cool down the needle to prevent thread break.

4. Speed reducer: for some extremely hard and stiff synthetic slings for example high density polyethylene fibers, the sewing needle penetration force probably not enough, the speed reducer can increase 3 times needle penetration and great patching area.

5. Spare parts package: including all wear and tear parts such as shuttle hook, needle plate, shuttle race, presser foot, thread tension etc.), the spare parts package can support for 4-5 years, you do not need to purchase any parts during this period.

Above are basic points you need to consider before purchase heavy duty industrial sewing machine, please feel free to contact us if you have any additional question or concern.

Additionally if you do not have experience with industrial sewing machine please, please specify, we will completely assemble the machine (Ready to Sew), and deliver by large plywood case.